- Our Location

- 17 Van Praagh Avenue,

Milton Park, Harare

- working hours

- Mon - Fri : 8:00 Am - 5:00 Pm

Our Products

Our Products

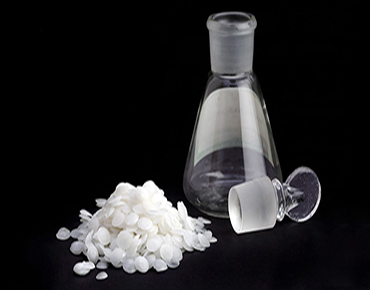

Sodium Hydroxide

Sodium hydroxide (caustic soda) is a co-product from the manufacture of chlorine using a solution of the readily available raw material, rock salt (sodium chloride). These factors contribute to it being the cheapest and most widely used strong alkali.

At room temperature, sodium hydroxide is a white crystalline odorless solid that absorbs moisture from the air. It is a manufactured substance. When dissolved in water or neutralized with acid it liberates substantial heat, which may be sufficient to ignite combustible materials. Sodium hydroxide is very corrosive. It is generally used as a solid or a 50% solution. Other common names include caustic soda and lye. Sodium hydroxide is used to manufacture soaps, rayon, paper, explosives, dyestuffs, and petroleum products. It is also used in processing cotton fabric, laundering and bleaching, metal cleaning and processing, oxide coating, electroplating, and electrolytic extracting. It is commonly present in commercial drain and oven cleaners.

Use in Mining

Chemical precipitation is a conventional technology used to treat mining-influenced water (MIW). Precipitation can be induced by the addition of an alkali that will bond with dissolved metal ions. Alkali sources include caustic sodium hydroxide (NaOH).Raising the pH with the use of alkaline agents causes certain dissolved metals (e.g., cadmium, copper, iron, lead, manganese, and zinc) to precipitate as hydroxides. A polymer may be added to enhance flocculation, and the solution may be transferred to a clarifier to separate the solids from the cleaned overflow effluent. The resultant metal-hydroxide sludge extracted from the bottom of the clarifier usually contains a large percentage of bound water, limiting the potential for reuse, and is disposed of as a solid waste. The amount of sludge generated can be reduced by employing a high-density sludge (HDS) treatment technique. In HDS processes, the precipitated hydroxide sludge is recycled to a conditioning tank, where it is mixed with the alkali reagent. The sludge/alkali slurry is then metered into the MIW to raise the pH and cause additional metal precipitation. This reconditioning of the sludge provides for precipitation sites for the dissolved metals to bond, increasing the overall density of the sludge in the clarifier underflow